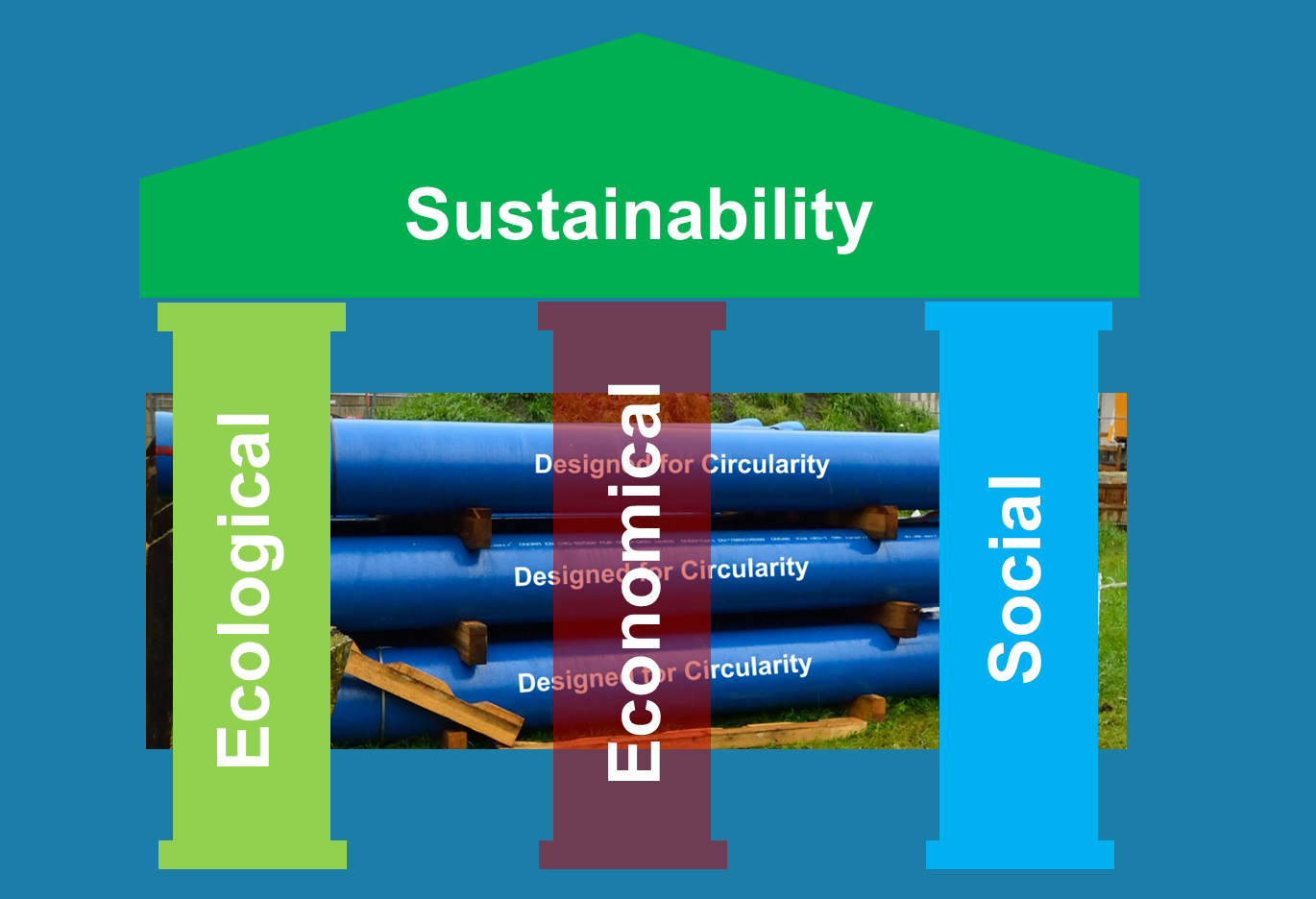

Sustainability is future viability

The circular economy is a prerequisite for sustainable transformation. This is a fact, as described in a recent statement by the German Council for Sustainable Development (RNE). It is also a fact that sustainability or sustainable development means „meeting the needs of the present without compromising the ability of future generations to meet their own needs“. It is important to consider the three dimensions of sustainability – economically efficient, ecologically sustainable and socially just – on an equal footing“ (BMZ) and to act accordingly! European manufacturers of ductile iron pipe systems have been acting accordingly for many decades: they supply network operators with products „Designed for Circularity“.

There is no contradiction between sustainability and economic success. On the contrary, the reorientation of the economy and financial markets means sustainability. The shift from a linear to a circular economy, which focuses on the entire value chain and aims to achieve closed resource cycles, is crucial to achieving a wide range of sustainability goals. We are facing major environmental and social challenges. Without a sustainable economy, we will not be able to achieve common goals such as the 17 Sustainable Development Goals (SDGs) or the EU’s climate targets as part of the European Green Deal.

EADIPS members have what it takes

The construction and transport sectors also play an important role in the use of raw materials. 90% of the mineral raw materials extracted in Germany are used in construction. At the same time, the construction sector generates more than half of Germany’s waste. The RNE therefore believes that circular construction must become the standard. Among other things, the German government should set specific targets for reducing the consumption of primary raw materials.

The concept of sustainability is particularly important to all our member companies. The high-quality pipes, valves and fittings made of ductile cast iron meet the stringent requirements for drinking water supply and waste water disposal systems – they are economical, ecological and socially responsible.

economic aspects

Investment in ductile cast iron pipe systems pays for itself low installation and operating costs and an exceptionally long service life:

- High installation productivity due to socket joints → Reduced labour costs

- No welding required → Reduces labour costs

- Installation independent of weather conditions → Reduces labour costs

- Often no sand bed required → reduces material and logistics costs

- No concrete abutments required for shear-resistant connections → Reduces material and logistics costs

- Connections can be angled → saves on fittings

- Wide range of fittings and valves avoids customisation → Reduces material and labour costs

- Lowest damage rates → Reduces operating, energy, repair and maintenance costs

- Service life in excess of 100 years → Minimises refurbishment budgets

ecological aspects

Ductile cast iron pipe systems are proven to deliver true environmental sustainability:

- Diffusion tightness → protects drinking water in all soil and installation conditions from environmentally harmful hydrocarbons and groundwater during wastewater transport

- Food-safe liners → ensure the hygienic and ecological transport of drinking water

- Scrap as a raw material → minimises the consumption of primary and fossil resources and reduces CO2 emissions

- Ductile cast iron is recyclable and can be reused → conserves resources for present and future generations

- Low maintenance and service costs with a long service life → avoids waste, minimises resource consumption and reduces CO2 emissions

social aspects

The high technical performance and top quality of ductile iron pipe systems (in accordance with the requirements of the quality guidelines) guarantee safety and reliability. At the highest level in all areas of water management and for generations to come:

- High material strength → allows operating pressures of up to 100 bar

- Durable external protection → resists mechanical and chemical attack, extending service life

- Static load capacity → allows maximum transverse and longitudinal loads with increasing traffic loads

- Connection → allows operating pressures of up to 100 bar, is root resistant and therefore suitable forin the sponge city

- Ductile cast iron → is non-combustible

- Extremely long service life over generations

- Restrained joints → allow for maximum tensile forces and are therefore ideal for trenchless installation

- Superior material properties → enable special applications in alpine regions, for fire-fighting pipelines, snow-making systems and hydroelectric power stations