Ductile Iron Pipe Systems

Designed for Circularity

Ductile cast iron pipe systems – creating and maintaining value

The production of high quality ductile cast iron pipes, valves and fittings for a safe, durable and efficient infrastructure is the business of our member companies. As a technical and scientific association, we have been representing their interests and providing advice, support and assistance since 1953. Our expertise and support are more in demand than ever, given the huge and sensitive challenges of our time, such as climate change, resource efficiency, supply chains, sustainability, the circular economy, etc.

For more than 140 years, cast iron has been considered a highly attractive material, and this appeal has not changed. On the contrary, today’s modern ductile cast iron pipe systems for the construction of water supply and sewerage pipelines – after many small and large development steps – have much more to offer. For operators of drinking water and wastewater networks and/or pipelines for hydroelectric power stations, there are countless good reasons and many advantages for choosing and relying on ductile cast iron pipe systems – ‚Designed for Circularity‘.

Products – made from ductile cast iron in Europe

The full members of EADIPS FGR produce ductile cast iron pipes, fittings and valves for drinking water, waste water, gas, etc., permanently protected by coatings and linings against external and internal corrosion and mechanical influences.

Cast iron pipes

Fittings

Valves

Resource efficiency and circular economy

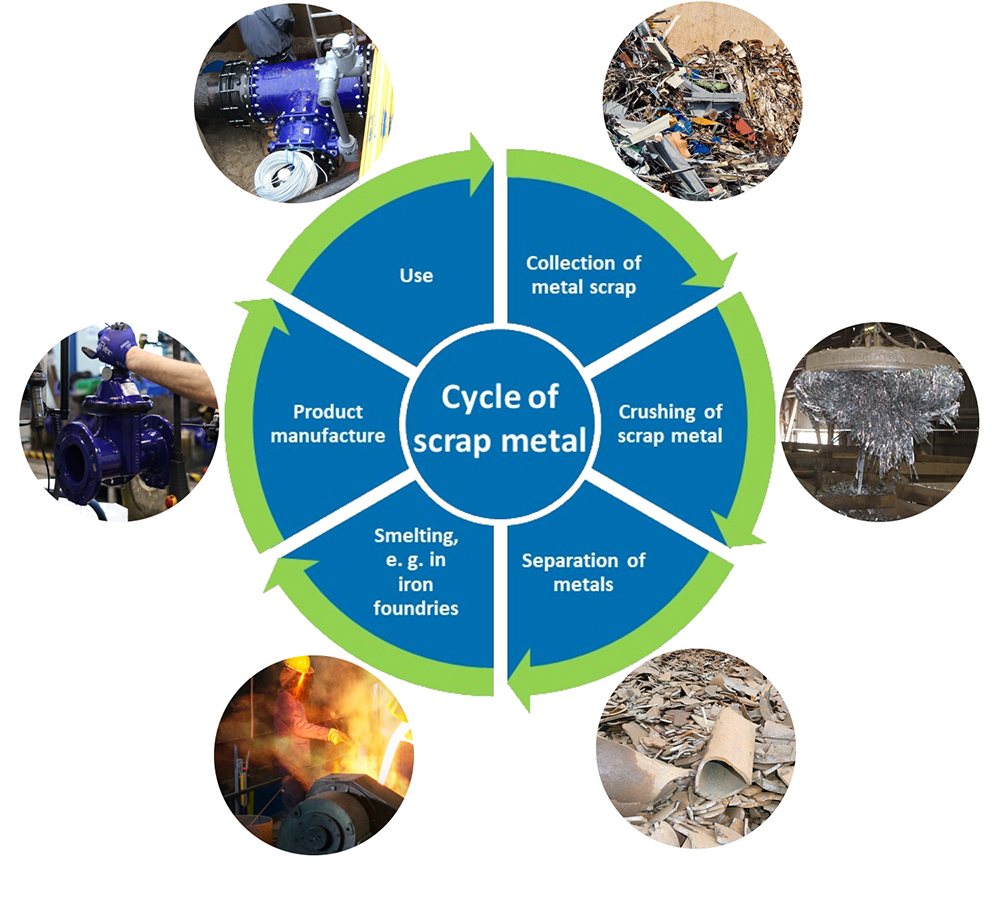

The world’s resources are very limited and we need to use them carefully. This means that products made from these materials should have a long service life and then not only be recyclable, but also reusable. The following sentence applies to ductile cast iron pipes:

I was a ductile iron pipe and I want to be a ductile iron pipe again!

Hardly any other pipe system can make the same claim, because steel scrap, cast iron scrap or even old excavated cast iron pipes are melted down to make ductile iron pipe systems, so that high-quality pipes, fittings or valves can be produced without any loss of quality. This way of thinking about material flows from a life cycle perspective takes into account the entire value chain from the extraction of raw materials. And that is why ductile cast iron is the material of today and tomorrow!

Onlinetools

only in German

For frequently asked design questions on DVGW and DWA regulations

Manual / E-book

Expertise in ductile iron pipe systems for planners, users and educators

Cast iron pipe systems for water and wastewater pipes

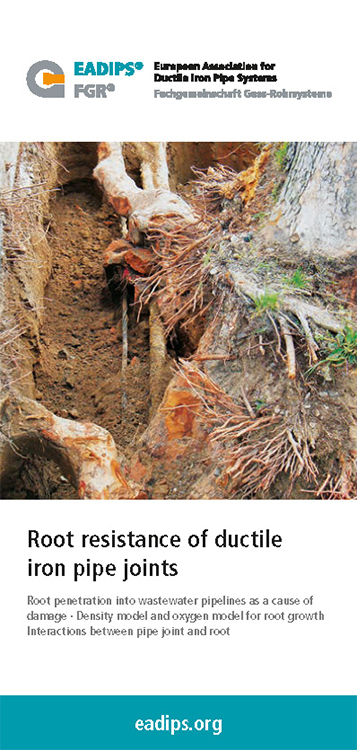

The first cast iron pipes (grey cast iron) were used as water pipes in Augsburg (1412) and Dillenburg Castle (1455) some 600 years ago. Today, after many major and minor developments, ductile cast iron pipes are produced using the centrifugal casting process (de-lavaud process) and ductile cast iron fittings and valves are produced using the sand casting process. The main applications for pipes, fittings and valves are water supply and waste water disposal. All products are permanently protected against mechanical damage and corrosion by external coatings and internal linings. Ductile cast iron pipes are used in both unpressurised networks (sewers) and high-pressure applications (e.g. pressure pipes in hydroelectric power stations) due to their freely selectable wall thicknesses and highly resilient, externally watertight and root-resistant pipe joints. Ductile iron pipe systems often have a unique selling point in difficult terrain and/or soil conditions, shallow installation depths (e.g. flat-covered pipes during installation) and high traffic loads.