Eight good reasons for ductile cast iron pipe systems

Safe – sustainable – future-proof

Products manufactured in Europe not only mean security of supply in the event of pandemics, crises and wars. They are backed up by regional production, short distances and forward-looking partners who ensure that the best water is transported by network operators to consumers with maximum safety. This is particularly true for ductile cast iron pipes, fittings and valves, which are manufactured in Europe not only from primary raw materials, but also from secondary raw materials – scrap. At the beginning of 2020, the members of EADIPS®/FGR® e. V. set out to make these and other advantages tangible. In the initiative “The best ground – a solid reason” for water and soil protection (www.solid-reason.org), the economic, social and technical advantages of European ductile cast iron pipes, fittings and valves are briefly and concisely presented in eight points against the background of the various challenges we face (Fig. 1).

The European Green Deal

The challenges we all face are well summarised in the introduction to the European Green Deal [1] (Fig. 2). It states:

“Climate change and environmental degradation are existential threats to Europe and the world. With the European Green Deal, we want to make the transition to a modern, resource-efficient and competitive economy that

- has zero net greenhouse gas emissions by 2050

- decouples its growth from resource use

- does not leave people or regions behind”.

On 14 July 2021, the European Commission presented proposals to achieve these objectives and make the European Green Deal a reality.

Eight reasons, eight topics

Our soil is more than just the ground on which we stand, move and live. It contains so much more: nutrients, water, air and all the infrastructure on which our lives depend. Whether it is drinking water pipes, sewers or electricity cables, without these essential supply and disposal networks, our lives would not look as they do or be as comfortable as they are. That is why it is important to use durable raw materials and safe materials in combination with sustainable concepts when constructing water supply and wastewater disposal systems. We work with ductile cast iron pipes, fittings and valves because the future can only be built on a good foundation today.

The best water

For us it seems normal that clean drinking water should come out of the tap – but this is not simple as it sounds (Fig. 3). A great deal of care lies behind this, not least in providing a good supply network which is subjected to all sorts of stresses, such as: soil movements due to traffic, construction works and minor earthquakes, impurities in the soil and groundwater and temperature fluctuations – all of these stresses have to be withstood by supply networks, thereby protecting our drinking water, our no. 1 life requirement! Only the best ‘packaging’ is good enough for this. Within secure and robust ductile iron pipe systems, good quality drinking water remains pH neutral and fresh; on top of this, they are impermeable, thus making sure that the drinking water does not pick up any taste from contaminated soils.

Höchste Sicherheit

Ductile iron pipe systems are more than simple components for our drinking water and waste water networks, for snowmaking facilities or power plant pipelines. They guarantee high security in all areas. On the one hand they are durable and robust and therefore optimum products for reliable pipe systems. On the other hand, European production also offers social and economic security.

The pipe system is only as safe as its individual components: Fittings, valves and pipes – all made of ductile cast iron.

Pipeline networks should guarantee stable supply and disposal for 100 years and more. During this time, networks are subject to many changes. The stresses imposed on pipe systems in the soil can alter on account of construction projects or increased traffic volumes. Soil loss caused by heavy rainfall can expose pipe systems beneath. Earth movements due to mining, earthquakes or landslides can alter these stresses massively. This is fine if the pipe system still functions robustly under these changes and the material properties are preserved. The concept of ductile cast iron pipe systems covers more than just the pipes for our drinking water The interplay of pipe, fitting and valve represents an equally important element (Fig. 4). A system is only as secure as its individual components installed upstream and downstream. The use of high-quality materials in valves and fittings plays an massive role here. Safety fittings such as double eccentric butterfly valves, needle valves or ball valves with their corresponding drives (e.g. brake-and-lift units), make sure that pressure surges are compensated, thus keeping the equipment as a whole secure. It is a matter of all components working together. Because it is only with a dependable, sustainable and robust pipe system (pipes, fittings and valves) that a good future can be built.

The resources cycle

We need to handle the limited resources of our environment responsibly and sustainably. Anyone who manufactures products from these resources must ensure that they can be used for as long as possible and that, at the end of their “life”, the materials are not only recyclable, but also part of the circular economy. It is precisely for this reason that we use ductile cast iron.

Piping systems in ductile cast iron can be in service for more than 100 years without problem and have the advantage that they can be recycled as often as necessary and so contribute to the protection of the environment (Fig. 5). This is in keeping with the principle that “this used to be a pipe, a fitting or a valve in ductile cast iron and it will once again become a pipe, a fitting or a valve in ductile cast iron”.

Pipes, fittings and valves do not consist of limited-availability fossil resources but of steel and cast-iron scrap which we source from predominantly regional material cycles. CO2 emissions are already being continuously reduced in production and “waste products” are fed back into the product cycle. Not only do our ductile iron pipe systems protect limited resources. The soil, also a resource, can be treated with care as well if the correct pipe is selected for the available soil.

#reduceplastic

Plastic is ubiquitous and it is difficult to conceive of our everyday life without it. But we are learning more and more about the growing risk which plastic represents for us and our environment (Fig. 6). For our good ground we recommend pipe systems made of ductile cast iron.

Already around 40% of the supply pipelines for drinking water in Germany are made from different types of plastic [2]. These drinking water pipes are recyclable – they can be used to make other pipes and other products, such as park benches and foils. However, there are limits to the use of recycled plastic in drinking water pipes: The use of recycled plastic is limited to the use of recirculated material (leftovers and offcuts) that is generated by the manufacturer itself, is not contaminated and has not yet been placed on the market [3]. Cast iron, on the other hand, is 100% recyclable at the same quality level without any loss in value. This means that not only the recycling economy, but also the circular economy can be realised – even in the drinking water sector!

Locally sourced mains water supplied via the municipal drinking water network is good for the environment. Mineral and table water, by contrast, is filled into bottles and transported by road, which requires a thousand times more energy than is needed for the provision of mains water from the drinking water network. The use of ductile cast iron drinking fountains, such as those used in Berlin for example, supplies thirsty people with fresh, cool drinking water quickly, simply and free of charge and sustainably supports the environmentally friendly consumption of drinking water. The drinking fountains can be used as “refill stations” and so combat the mountains of plastic bottle waste.

Cooler cities

Nowhere else is global warming, and the rising temperatures associated with it, so clearly felt as in our towns and cities. In the summer months, surfaces sealed with asphalt and concrete do not cool down and, in case of heavy rainfall, are unable to absorb water.

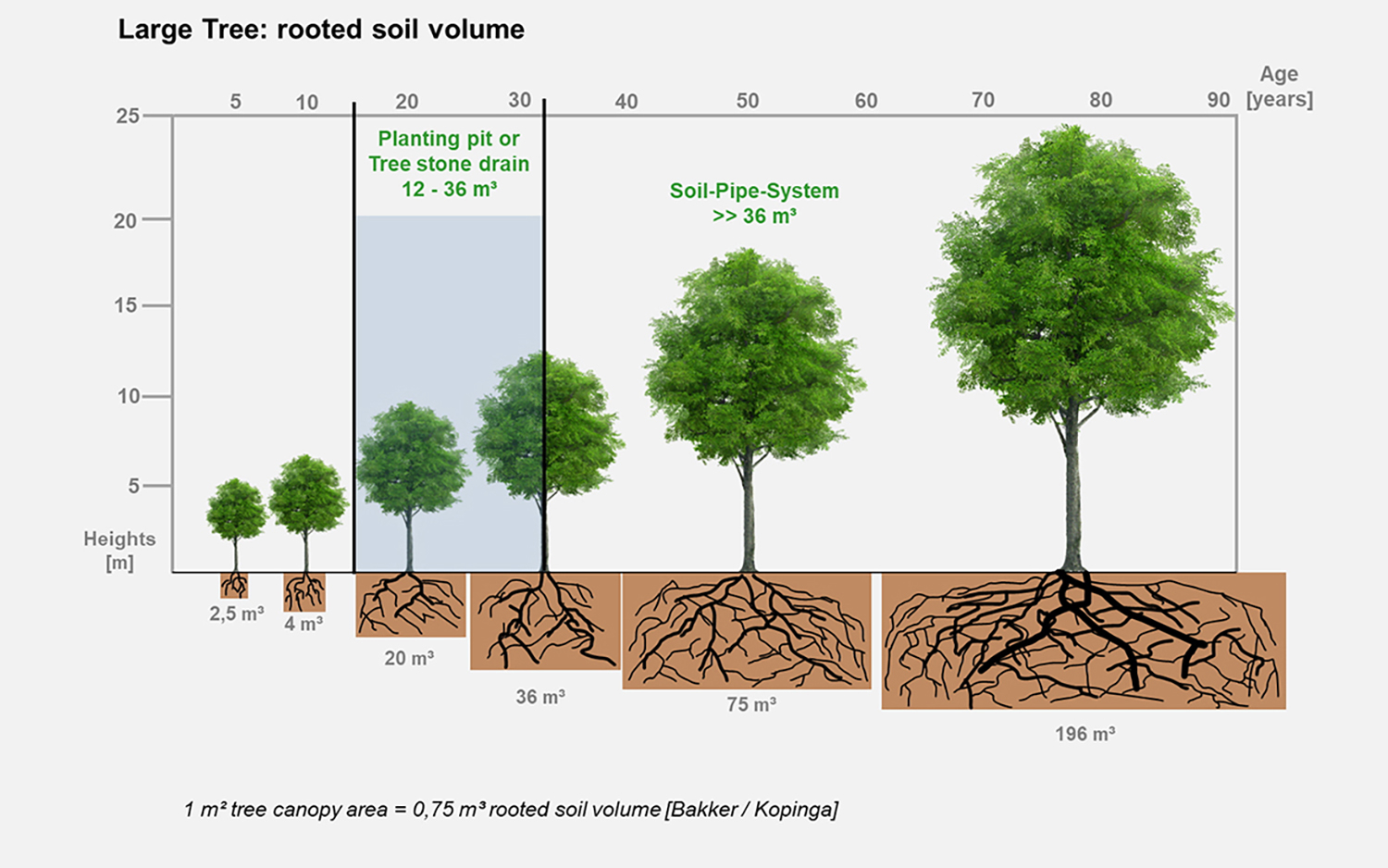

The consequences of this are heat islands in the summer, flooding and inundated basements when it rains. Meaning that life in the city is becoming not only more difficult but also less healthy. The solution lies in so-called Sponge Cities, where space is left in the ground for rainwater and for trees: space to breathe, to grow and to store water (Fig. 7). So that green areas and trees can cool our cities and make them habitable even during longer periods of drought or heat. For these sponge cities, space is needed underground. In pipe trenches with robust and root-resistant piping systems, this space can be made available to a sufficient extent. Ductile iron pipes with their flexible joints and with a cement mortar coating are robust and root-resistant and so are an important key to cooler cities.

The R&D project “BoRSiS – soil pipe system as an innovative element of climate-adjusted urban drainage”, which was launched on 1st October 2021 with the participation of EADIPS®/FGR®, pursues the further implementation of the sponge city principle in the street space [4]. The objective of BoRSiS is to use the pipe trenches of pipes under pavements or streets (during heavy rainfall) and to release water with a time delay (during dry periods) to irrigate urban trees. By using the pipe trench, an extended storage area for rainwater and the root zone is available without the need for additional surface area (compared to infiltration trenches).

Regional manufacturing

Durable, recyclable and regional: our cast iron pipe systems are not only sustainable in the production of the material but also in terms of transport because they are produced in our European factories (Fig. 8). So we are providing important jobs for the region and avoiding global transport routes. But a sustainable production process offers even more advantages: we can ensure that our claims to environmentally friendly production continue to be safeguarded and all stages of production are independently optimised. In doing this, we are building on the many years of expertise of our colleagues, which is substantially responsible for the high quality of our products. This means that ductile iron pipe systems, produced in Europe, stand for more than simply a reliable supply of drinking water.

Short distances

Regionality offers the invaluable advantage of short distances – for consultation, for decision-making, for collaboration, but also for logistics. This means that global price fluctuations, delivery difficulties or bottlenecks are not part of our everyday experience. Our work and our logistics are just as reliable, robust and sustainable as our products are.

But short distances also make a fast ordering and delivery process possible. In case of need, customers can obtain any pipes, fittings or valves that they are lacking either by collecting them themselves or by having them delivered promptly, all without delay or red tape.

Partners with vision

It takes many different processes to produce a ductile iron pipe. Equally, it takes many committed people to prepare the ground for a good future. For this reason, we count on our network of reliable partners with whom we enhance and extend our ductile iron pipe systems (Fig. 9).

By working together with the right partners, it is possible to act locally and change things globally: EADIPS, with all its member companies, stands for sustainability, best water quality, #reduceplastic, security of supply, regional production and conservation of resources.

Municipal partners

The Good Reason Initiative is supported by municipal partners who identify with its objectives. The first partners to join the “Good Reason” initiative for soil and water protection were the municipality of Hall in Tirol and Hall AG as the water supply company (Fig. 10). The partners attach particular importance to “short distances” and the “cycle of resources”. By procuring local products and offering local services, they not only practice exemplary environmental protection, but also ensure a safe water supply for the population.

Summary

In addition to the war in Ukraine, the coronavirus pandemic has shown us the impact of the breakdown of global supply chains. In addition, the European Green Deal poses major challenges to both the economy and the operators of supply and disposal networks in order to achieve zero net greenhouse gas emissions by 2050, to decouple growth from resource use and to leave no one, neither people nor region, in the lurch. The members of EADIPS®/FGR® are aware of these challenges and, early on, summarised the essential aspects required for this in eight good reasons and, building on this, launched the initiative “The good ground – a solid reason” and found municipal partners to support the initiative.

Author:

Christoph Bennerscheidt, EADIPS FGR

![The European Green Deal [1] focuses on „mobilising industry for a clean and circular economy“. The European Green Deal [1] focuses on „mobilising industry for a clean and circular economy“.](https://en.eadips.org/wp-content/uploads/2024/09/Coolere-Staedte-Bild-05-02-EN.jpg)